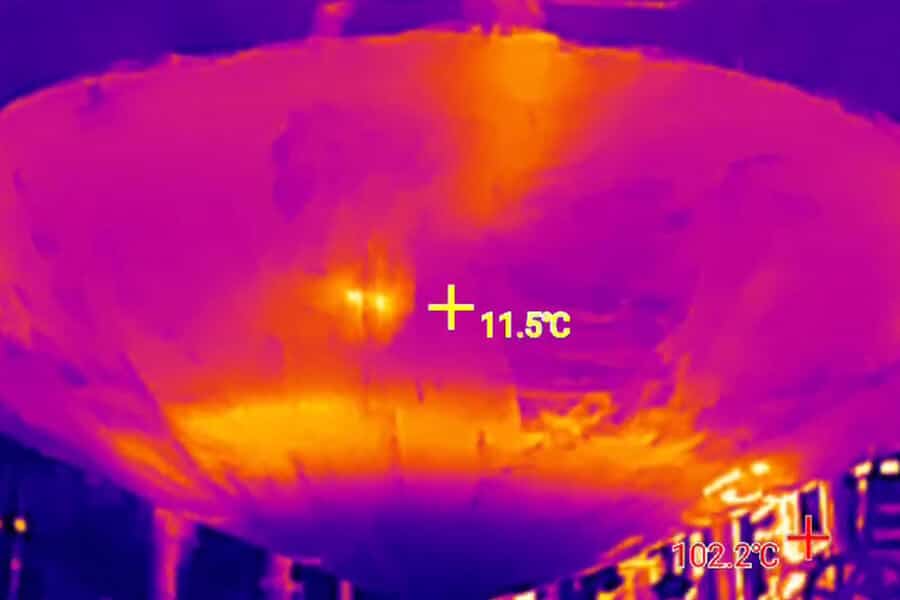

It might look like a scene from “Predator”, but this image was what enabled us to carry out a repair on our brew kettle recently.

Repairing equipment in a brewery can often require some creative problem-solving, as the issues can be so specialised that help is not always readily available. Recently, we encountered such an issue with our 4000-litre brew kettle, where steam was leaking from the steam jacket into the gap between the inner and outer skins. Our kettle is a double-skinned vessel. It consists of:

The steam leak was somewhere in the lower jacket. Since the kettle is a sealed unit, accessing the leak would require cutting a hole in the outer skin. The challenge was to find the precise location for this access point.

To locate the steam leak, I bought an infrared camera attachment for a smartphone. This little device allowed us to visualise where the outer skin heated up first when the kettle steam was switched on. A small yellow patch of heat immediately revealed itself on the outer skin, indicating the location of the steam leak.

A local welder was then contacted to open the outer skin at that spot. The leak was exactly where the camera showed it would be, and it was easily repaired with a small weld.

Join our mailing list and receive a 10% off voucher for your first purchase!

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |